This tiny carrier board makes it easy to integrate the Sharp GP2Y0D810Z0F and GP2Y0D805Z0F digital distance sensors into your project by providing all of the required external components, an LED for feedback about the output state, and 0.1"-pitch, three-pin interface to the sensor.

Overview

The GP2Y0D805 and

GP2Y0D810 are Sharp's smallest and fastest distance sensors, and our tiny carrier board for these sensors includes all of the external components required to make them work. With a sample rate of almost 400 Hz and a sensing distance to 5 cm (GP2Y0D805) or 10 cm (GP2Y0D810), this sensor provides an attractive alternative to shorter-range LED-phototransistor reflectance pairsand longer-range but slower sensors such as the Sharp GP2Y0A21YK0F analog distance sensor.

However, these sensors require external components and have a non-standard 1.5 mm pitch, which can make them difficult to integrate into projects based on a 0.1" pitch. This carrier board includes these components and provides a 0.1"-pitch, three-pin interface: ground, power, and output.

Note: this product requires a Sharp

GP2Y0D810Z0F or

GP2Y0D805Z0F sensor (sold separately). We also offer a version of this carrier board assembled with a GP2Y0D810Z0F and a version

assembled with a GP2Y0D805Z0F.

Using the Carrier Board

|

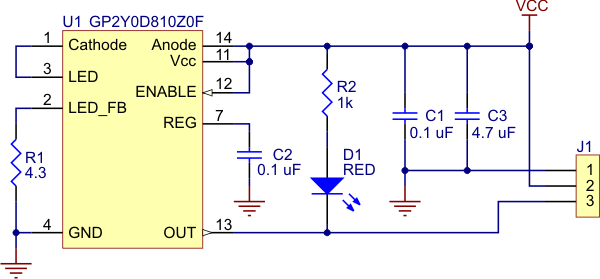

| Pololu carrier with Sharp GP2Y0D810Z0F digital distance sensor 10cm. |

You will need to solder the sensor to the carrier board so that the solder connections are made on the component-side of the board and the sensor package presses against the component-free side of the board. Once the sensor is soldered in, the Pololu carrier board lets you interface with the GP2Y0D810 or GP2Y0D805 sensor using a three-pin 0.100" connector, such as the included 3x1

straight male header strip and 3x1

right-angle male header strip. You can connect to these pins with a servo cable or with a custom-made cable using pre-crimped wires and a

3x1 crimp connector housing.

The square pad is ground, the middle pad is VIN (2.7 - 6.2 V), and the remaining pad is the sensor output, OUT. Depending on your power source, you might notice an increase in performance by placing a large (>10 uF) capacitor between power and ground somewhere near the sensor.

A red LED on the back of the PCB lights when the output is low, indicating that the sensor is detecting something. If so desired, you can disable this LED by cutting the trace between it and the OUT pin where it is marked on the silkscreen or by desoldering the LED.

The GP2Y0D810Z0F and GP2Y0D805Z0F have an optional enable input that can be used to put the sensor into low-power mode. The Pololu carrier board connects this input to Vcc so that the sensor is always enabled, but you can solder a wire to the pad labeled "enable"Â on the back of the PCB if you want control over this input. Note that you will need to cut the trace that connects the enable line to Vcc on the PCB if you want to be able to disable the sensor. This trace is marked on the silkscreen, and there is a caret that indicates where we suggest you make the cut.

The carrier board has a 0.086" mounting hole for a #2 screw. You can make the module more compact by cutting or grinding off this portion of the PCB if you do not need the mounting hole.

|

| Pololu carrier for Sharp GP2Y0D810Z0F and GP2Y0D805Z0F sensors schematic diagram. |

===================================

FAQs

===================================

This sensor isn't behaving as I expect: I'm getting intermittent detection much farther than the maximum range of the sensor and it's not detecting objects within the advertised detection range. What's wrong?

Issues like this can be the result of power supply problems, especially since this sensor draws power in short, large bursts, so make sure your power supply is capable of delivering the necessary current. If you experience this problem, try adding a 10 uF or so capacitor across the sensor's power and ground near the sensor; this compensates for an inadequate power supply and typically restores normal functionality.

No recommended products at the moment.

No recommended products at the moment.